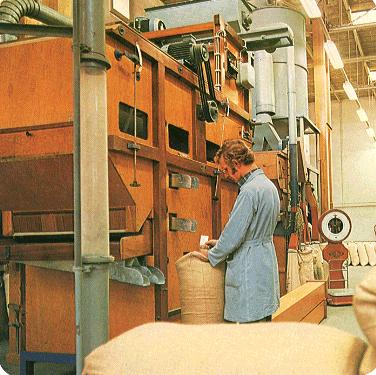

Many specialized pieces of equipment are used so clean and sort seeds. The airscreen machine pictured here is also called a fanning mill. The airscreen machine is a basic seed-cleaning machine used to condition all types of seeds. This machine uses a combination of airflow and perforated metal or wire screens to separate seeds on the basis of size, specific gravity, and resistance to airflow. Many sizes of airscreen cleaners exist from very small two screen farm models to large industrial cleaners with seven or eight screens and three or four air separations. The machine works in three different ways. Seed first enters the machine by gravity from the feed hopper. In some machines, it falls directly into a scalping screen, which allows the good seed to fall through, while separating out the large seeded species and foreign material. In some models of the airscreen machine, the seed falls through an aspirating air stream first which blows off the lighter material from the seed mass. The last operation grades the seed by allowing the good seed to ride over the screen perforations, while smaller seed and debris fall through the screen. All airscreen machines use these same three principles, though their sequence may differ. Screens in the machine are constructed of either perforated sheet metal or woven wire mesh in a wooden frame. The openings in the metal screens may be round, oblong, triangular while openings in the wire mesh screens are either square or rectangular. These screens can be easily changed and there are dozens of sizes to choose from.